- Products

- Speakers

- Tower / Floorstand

- 1528 Tower 8

- 1723 Tower THX

- 1723 Tower S THX

- 1961 Tower

- View all Compare

- Bookshelf / Standmount

- 1528 Monitor 8

- 1528 Bookshelf 8

- 1528 Slim 8

- 1723 Monitor THX

- 1723 Monitor S THX

- 1723 Bookshelf S THX

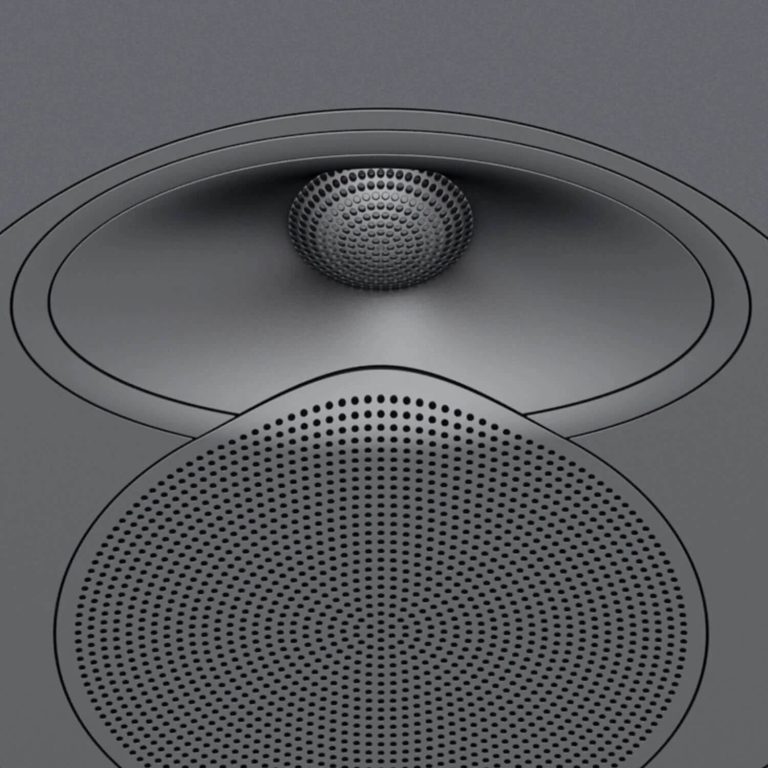

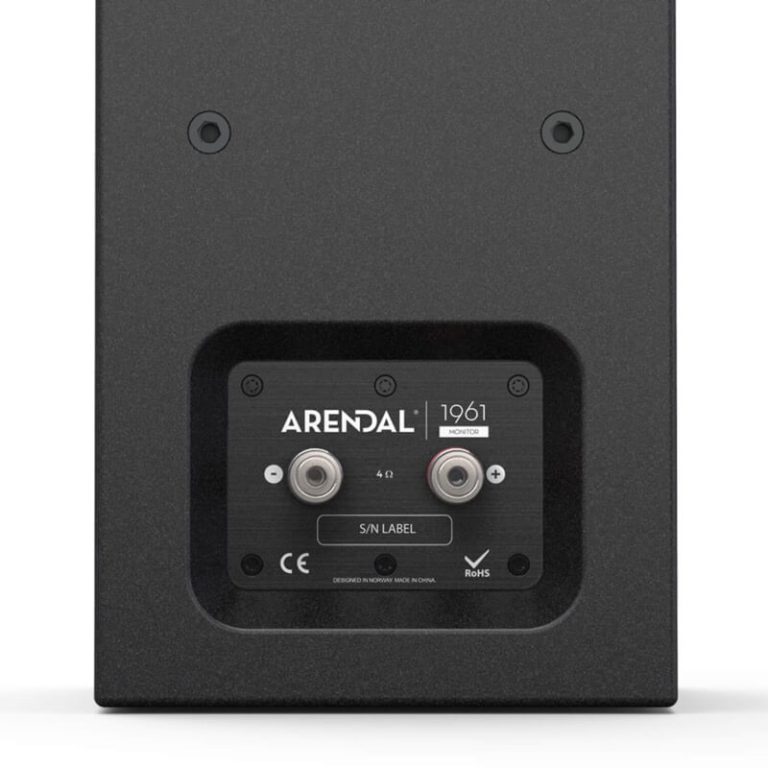

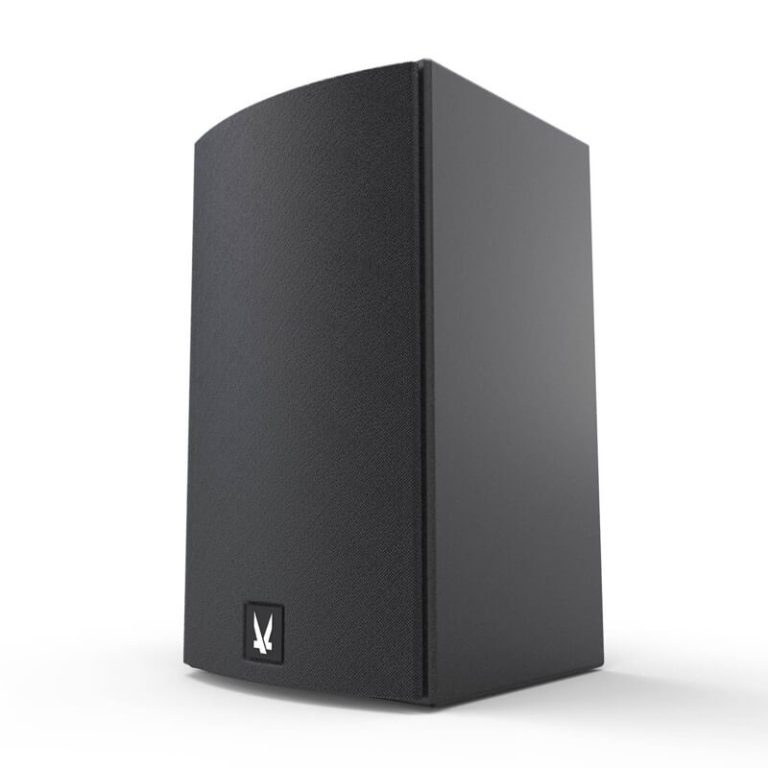

- 1961 Monitor

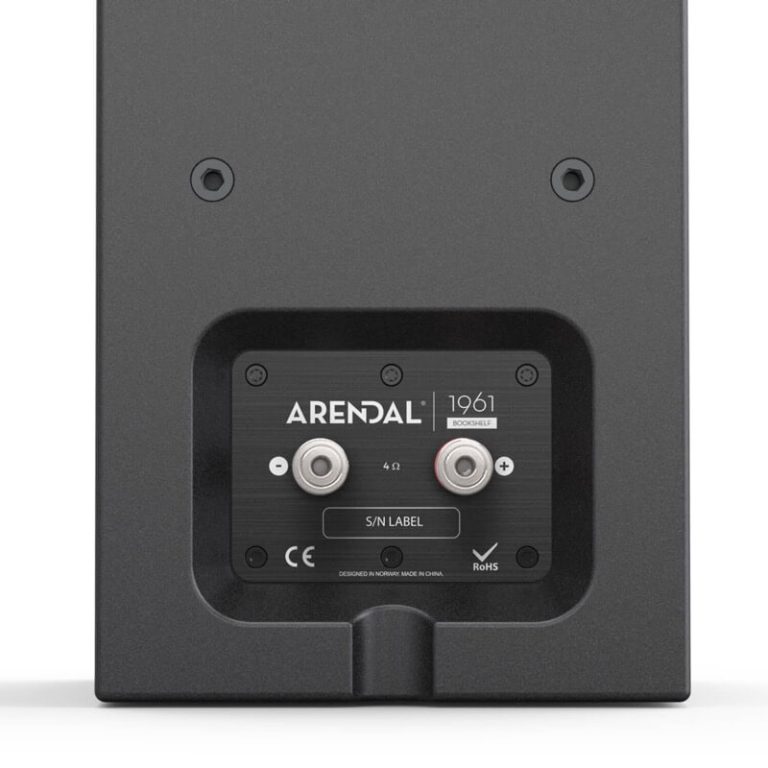

- 1961 Bookshelf

- View all Compare

- Surround / Height / On-Wall

- 1528 Slim 8

- 1723 Surround THX

- 1723 Surround S THX

- 1723 Height S

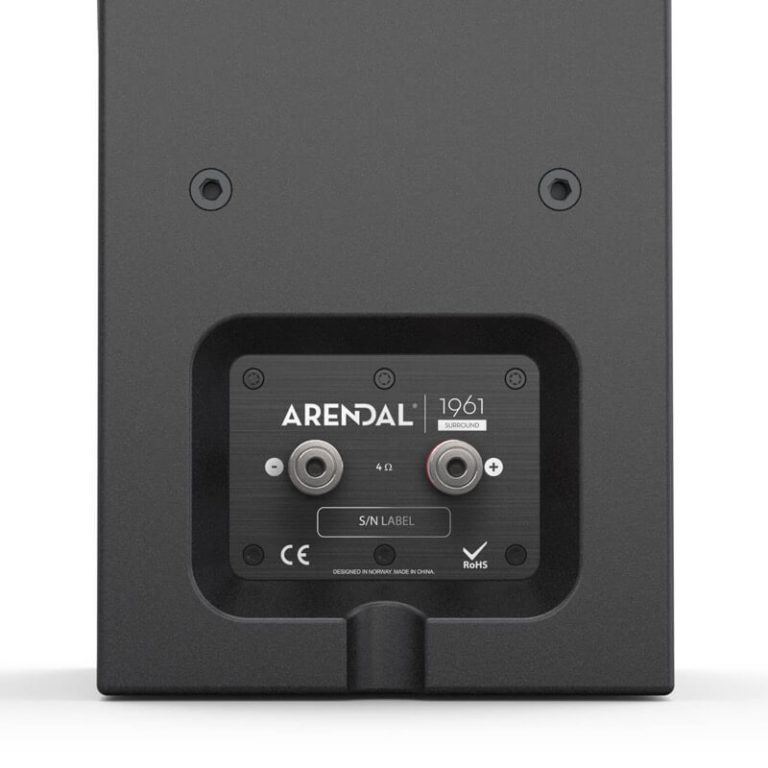

- 1961 Surround

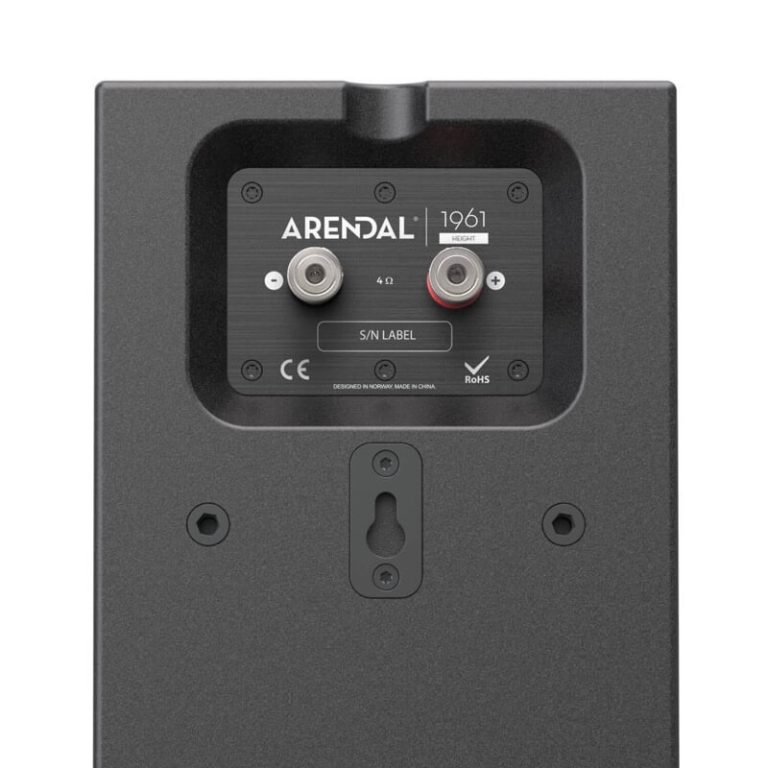

- 1961 Height

- View all Compare

- Subwoofers

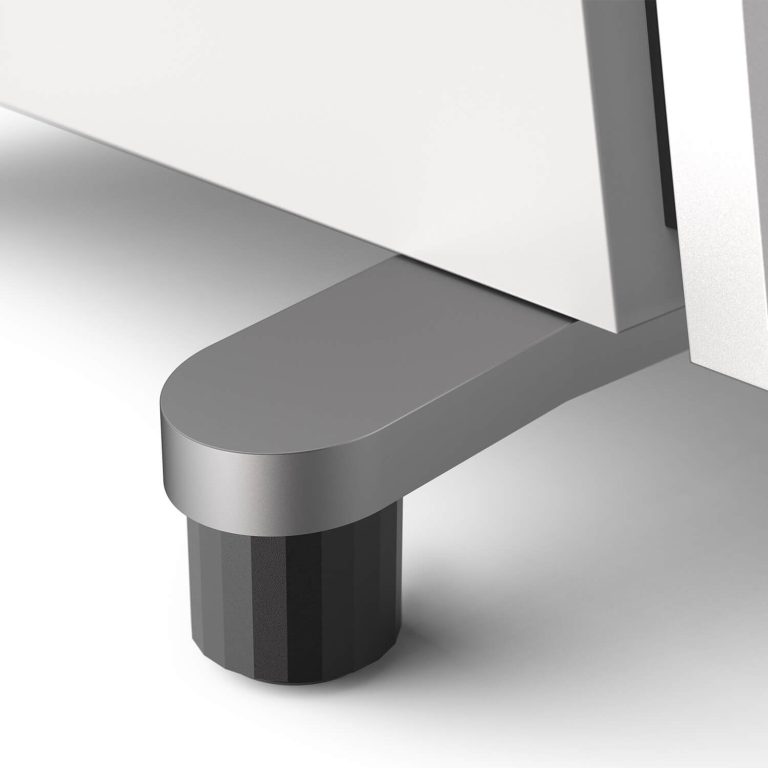

- Stand

- Accessories

- Series

- 1528 Series

- 1723 THX Speakers

- 1723 S THX Speakers

- 1723 Subwoofers

- 1961 Series

- 1961 Subwoofers

- Our Values

- About us

- Jan’s Story

- Reviews & Awards

- Customer Benefits

- 1 Year Premium Upgrade

- Ambassadors

- PARTICIPATE

- Store

- Outlet

- Support

- Career

- Ambassador Program

- Arendal Club

- Contact us

- Login / Create account

- View All

- 1528 Monitor 8

- 1528 Bookshelf 8

- 1528 Slim 8

- 1723 Monitor THX

- 1723 Monitor S THX

- 1723 Bookshelf S THX

- 1961 Monitor

- 1961 Bookshelf

- Compare Speakers

- View All

- 1528 Center 8

- 1528 Center+ 8

- 1723 Center THX

- 1723 Center S THX

- 1961 Center

- Compare Speakers

- View All

- 1528 Slim 8

- 1723 Surround THX

- 1723 Surround S THX

- 1723 Height S

- 1961 Surround

- 1961 Height

- Compare Speakers