- Products

- Subwoofers

- Speakers

- Accessories

- Series

- 1723 Series

- Our Values

- About us. About you.

- Jan’s Story

- Reviews & Awards

- Customer Benefits

- Ambassadors

- PARTICIPATE

- Store

- Outlet

- Support

- Career

- Ambassador Program

- Arendal Club

- Login / Create account

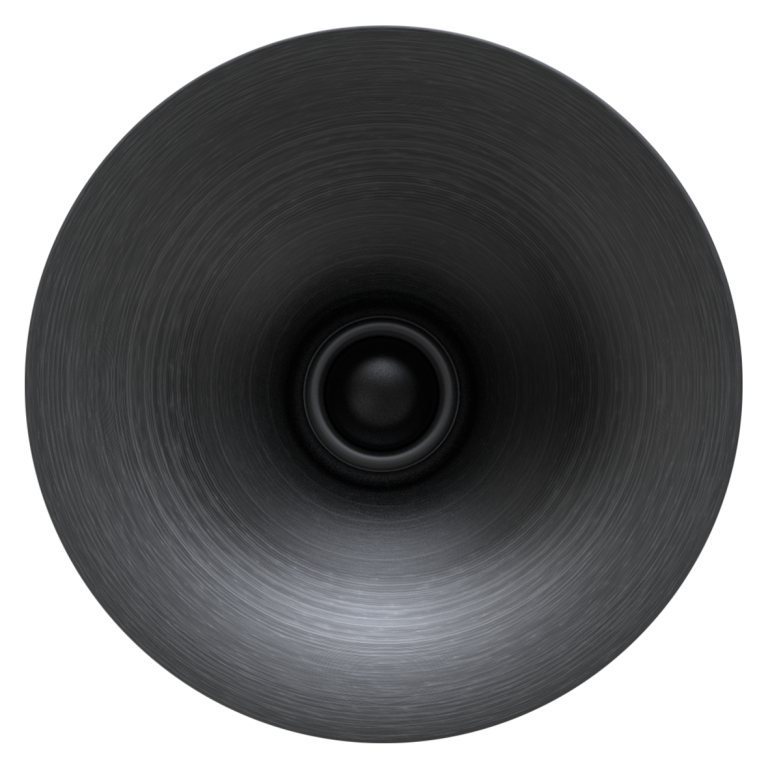

Subwoofers

This is an exciting category. Subwoofers are just like a big screen, for the full experience. Incredible power-handling, dynamics, detailing, and features from another world.

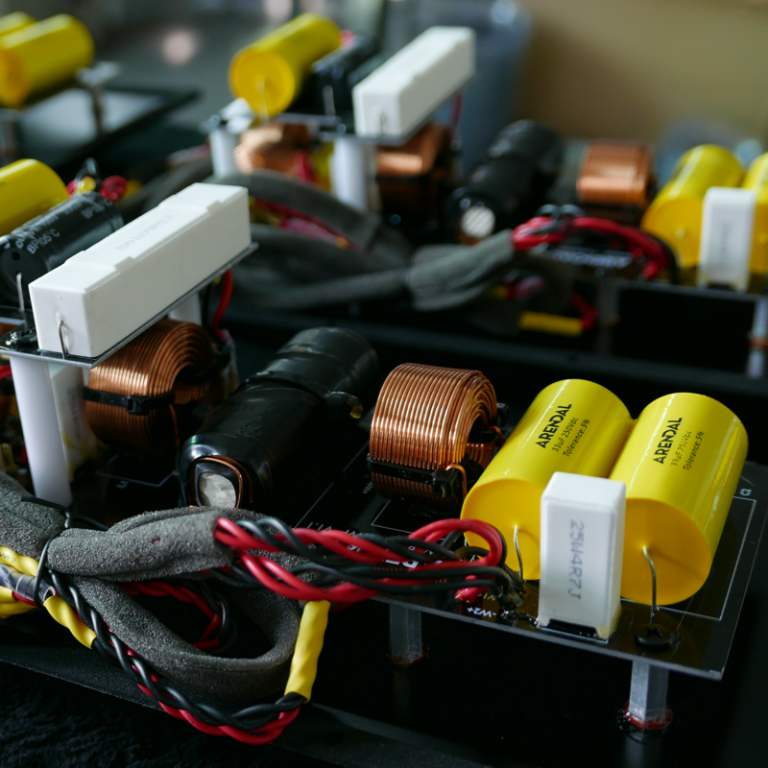

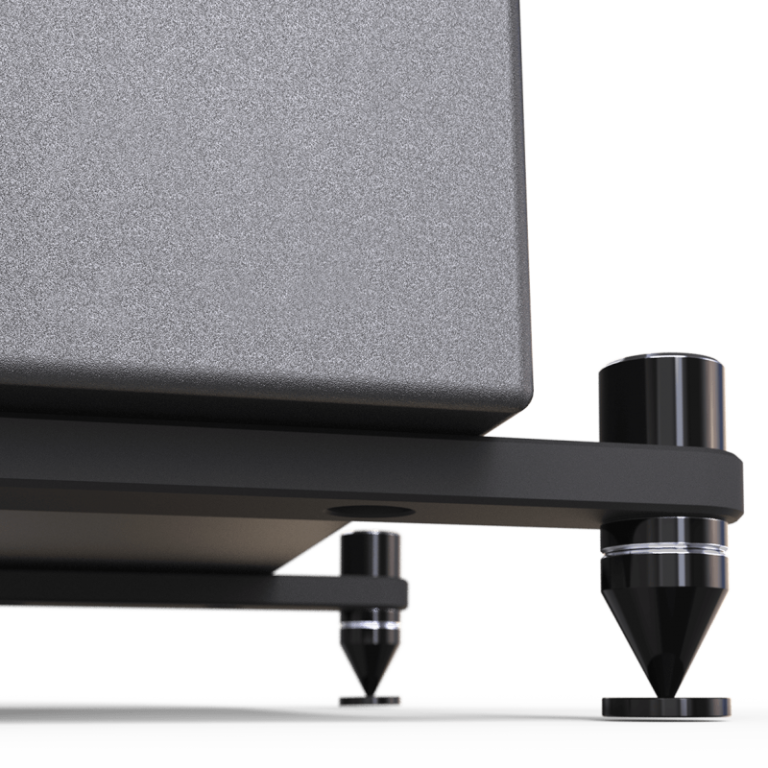

1723 Series

1723 THX is the Arendal Sound statement of intent to deliver a quality of design, materials, and fidelity. There are no corners cut in material specification, whether you can see them or not.

- Store

- Support

- Career

- Ambassador Program

- Arendal Club

PARTICIPATE